Riteway Brake Dies

The Pinnacle of Precision Tooling

Offset Dies

Offset dies form two 90 degree bends in one stroke. Dimensions show amount of offset from inside to outside of metal thickness. Sizes shown are suitable for mild steel to 18 gauge. Often metals and heavier gauges of mild steel can be formed depending on size of offset and press brake capacity available.

Formed material bent from offset die

Offset in the process of being formed

Formed material bent from offset die

For forming metal thickness offsets, best results are obtained in die set #84. Dies have a back-up leader to reduce material spreading.

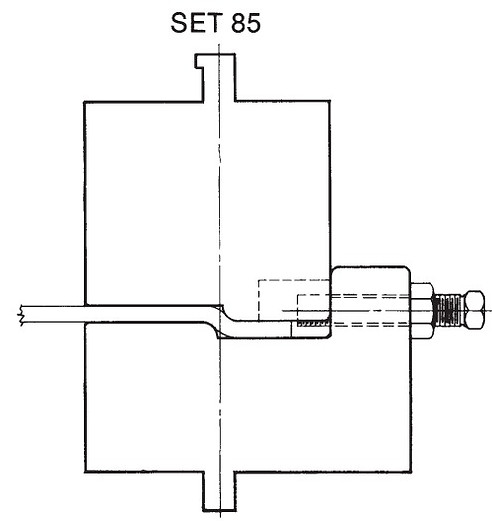

Die set #85 is recommended on heavier gauge stock for open angle offset.

Open angle offsets adjustable to 5/16" can be obtained in die set #86. Shimming behind reversible blocks changes depth of offset. Rotation of blocks changes the radius. Each corner has a different radius to allow for various material thickness.

If the offset is 1" or less from the edge, set #87 can be used. Dies have a back-up leader so minimized spreading and sharper offsets will result.